Hypertherm Powermax 45 Sync

Powermax 45 SYNC Plasma Cutter

For metal workers who want the most versatile system available to gouge, cut, and mark, Powermax45 SYNC delivers the best return on investment with a patented single-piece cartridge, up to 5x longer consumable life, and greater cutting power than higher-amperage competitors.

APPLICATIONS

Drag cutting

For dragging the torch directly across the work piece

Fine feature cutting

For narrow kerf width with minimal dross and heat affected zone

Max control gouging

For precise metal removal, shallower gouge profiles and light metal washing

Max removal gouging

For aggressive metal removal, deep gouge profiles, and extreme metal washing

Mechanized cutting

For portable automation and table cutting

Marking

For scoring, indicating part identification, hole or weld locations

BENEFITS

Standard configurations

Below are the standard system configurations, which include a power supply, torch and work cable.

|

CSA |

75° hand torch |

75° and 15° hand torch |

180° full-length machine torch |

180° full-length

machine torch |

|||

|---|---|---|---|---|---|---|---|

|

|

6.1 m (20′) |

15.2 m (50′) |

6.1 m (20′) and 7.6 m (25') |

7.6 m (25′) |

15.2 m (50') |

7.6 m (25') and 6.1 m (20') |

|

|

Powermax45 SYNC power supplies |

|

|

Without remote pendant |

Without remote pendant |

With remote pendant |

Without remote pendant |

With |

|

Standard power supply |

|

|

|

||||

|

Power supply with CPC port and voltage divider |

|

||||||

|

Power supply with CPC port, voltage divider and serial port |

|

|

|

088584 |

|

|

|

Custom configurations

Select power supply, torch, work cable, cartridges, and other components

Power supply options

|

|

Standard power supply |

Power supply with CPC port and voltage divider |

Power supply with CPC port, voltage divider and serial port |

|---|---|---|---|

|

Powermax45 SYNC 230V CSA |

|||

|

Powermax45 SYNC 480V CSA |

|

|

Cable options

|

|

Work cables |

Control cables |

||||

|---|---|---|---|---|---|---|

|

Cable length |

Hand clamp |

Remote pendant |

CNC, spade connector, divided voltage |

CNC, spade connector, no divided voltage |

RS-485 Serial comm, unterminated |

RS-485 Serial comm, D-sub |

|

7.6 m (25') |

223236 |

223239 |

||||

|

15.2 m (50') |

128651 |

228351 |

023279 |

223237 |

223240 |

|

|

22.8 m (75') |

223127 |

128652 |

|

|

|

|

SPECIFICATIONS

Cut capacity

| Capacity | Thickness | Cut speed |

|---|---|---|

| Recommended | 16 mm (5/8″) | 500 mm/min (20 ipm) |

| Severance (hand cutting) | 29 mm (1-1/8″) | 125 mm/min (5 ipm) |

| Pierce* | 12 mm (1/2″) |

*Pierce rating for handheld use or with automatic torch height control.

Maximum removal gouging

| Capacity | Metal removal rate | Groove profile |

|---|---|---|

| Typical gouge | 3.4 kg (7.5 lbs.) per hour | 3.2 mm D x 6.8 mm W (0.12″ D x 0.26″ W) |

General specifications

|

Input voltages |

CSA 200–440 V, 1-PH, 50/60 Hz 480 V, 3-PH, 50/60 Hz 480 V, 3-PH, 10 A @ 6.9kW

CE 230 V, 1-PH, 50/60 Hz 400 V, 3-PH, 50/60 Hz |

|---|---|

|

Kilowatt output |

6.9 kW |

|

Input current |

CSA 200-240 V, 1-PH 39/32 A @ 6.5 kW

CE 230 V, 1-PH, 33 A 400 V, 3-PH, 10 A |

|

Output current |

9–45 A |

|

Rated output voltage |

155 VDC |

|

Duty cycle @ 104° F |

CSA 50% @ 45 A, 200–240 V, 1-PH 60% @ 41 A, 200–240 V, 1-PH 100% @ 32 A, 200–240 V, 1-PH 50% @ 45 A, 480 V, 3-PH 60% @ 41 A, 480 V, 3-PH 100% @ 32 A, 480 V, 3-PH

CE 50% @ 45 A, 230 V, 1-PH 60% @ 41 A, 230 V, 1-PH 100% @ 32 A, 230 V, 1-PH 50% @ 45 A, 400 V, 3-PH 60% @ 41 A, 400 V, 3-PH 100% @ 32 A, 400 V, 3-PH |

|

Open circuit voltage (OCV) |

CSA 275 VDC 200-240 V 275 VDC 480 V

CE 265 VDC 400 V |

|

Dimensions with handles |

442 mm D; 173 mm W; 357 mm H (17.4″ D; 6.8″ W; 14.1″ H) |

|

Weight w/6.1 m (20′) torch |

CSA 14 kg (31 lbs.)

CE 15 kg (33 lbs.) |

|

Gas supply |

Cutting: air (clean, dry, and oil-free), nitrogen, F5 Gouging: air (clean, dry, and oil-free), nitrogen, F5 Marking: air (clean, dry, and oil-free) |

|

Recommended gas inlet flow rate/pressure |

188 I/min @ 5.9 bar (400 scfh @ 85 psi)

|

|

Input power cable length |

3 m (10′) |

|

Power supply type |

Inverter – IGBT |

|

Engine drive requirement |

12.5 kVA (10 kW) for full 45 A output |

|

Electrical efficiency |

90% |

|

Certifications |

CSA - certified for use in the Americas and Asia, except China CE - for use in

Europe, Australia, New Zealand, Belarus, Kazakhstan, Serbia, |

|

Warranty |

Power supplies have a 3-year warranty and torches a 1-year warranty |

Mechanized and FineCut for machine torches

SmartSYNC torches feature RFID capability that when coupled with a Hypertherm cartridge will communicate with a Powermax SYNC system to automatically set the amperage and process on the power supply. Available in handheld, mechanized and robotic torch configurations.

|

|

Hand torches |

Machine torches |

Robotic/Mini |

|||

|---|---|---|---|---|---|---|

|

|

75° |

15° |

180° |

180° |

90° |

45° |

|

4.5 m (15′) |

|

|

|

059733 |

|

|

|

7.6 m (25') |

059731 |

059729 |

||||

|

10.7 m (35') |

|

|

|

|

|

|

|

15.2 m (50') |

059735 |

059732 |

059730 |

|||

|

22.8 m (75') |

|

059767 |

059766 |

|||

|

|

Long torches |

|||

|---|---|---|---|---|

|

|

0.6 m (2′), 45° |

0.6 m (2′), 90° |

1.2 m (4′), 45° |

1.2 m (4′), 90° |

|

4.5 m (15′) |

|

|

|

|

|

7.6 m (25') |

|

528114 |

|

|

|

10.7 m (35') |

|

|

|

|

|

15.2 m (50') |

528116 |

528117 |

528118 |

528119 |

|

22.8 m (75') |

||||

Hypertherm cartridges

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Hypertherm cartridges for Powermax systems are manufactured to uphold our high standards for quality and reliability. As part of the manufacturing process, we test-fire each cartridge to ensure proper assembly and function. As a result, there may be burn marks on the tip of the cartridge. This is normal and not a sign of damage.

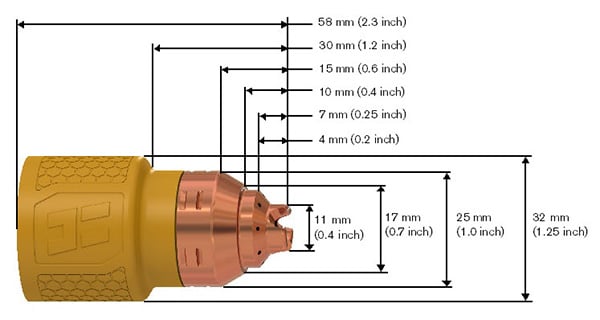

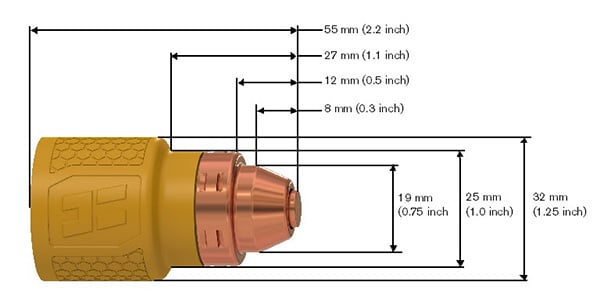

Drag cutting and FineCut for hand torches

Mechanized and FineCut for machine torches

Max removal and max control gouging