Powermax65 SYNC plasma cutter

The Powermax65 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for cutting and gouging up to 20 mm (3/4″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC® torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax65 SYNC maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

System information

Applications

Benefits

Specifications

Resources

Torches and consumables

SmartSYNC torches

SmartSYNC torches feature RFID capability that when coupled with a Hypertherm cartridge will communicate with a Powermax SYNC system to automatically set the amperage and process on the power supply. Available in handheld, mechanized and robotic torch configurations.

|

|

Hand torches |

Machine torches |

Robotic/Mini | |||

|---|---|---|---|---|---|---|

|

|

75° |

15° |

180° |

180° |

90° |

45° |

|

4.5 m (15′) |

|

|

|

059733 |

|

|

|

7.6 m (25') |

059726 |

059723 |

059719 |

059734 |

059731 |

059729 |

|

10.7 m (35') |

|

|

059720 |

|

|

|

|

15.2 m (50') |

059727 |

059724 |

059721 |

059735 |

059732 |

059730 |

|

22.8 m (75') |

059728 |

059725 |

059722 |

|

059767 |

059766 |

Hypertherm cartridges

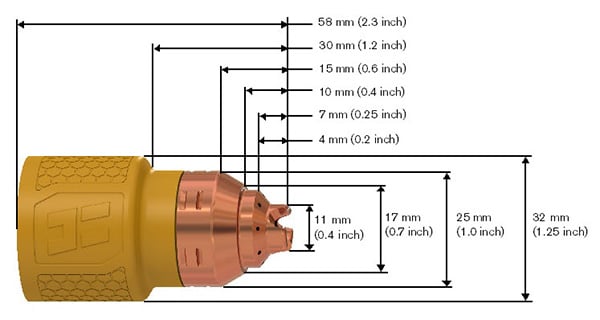

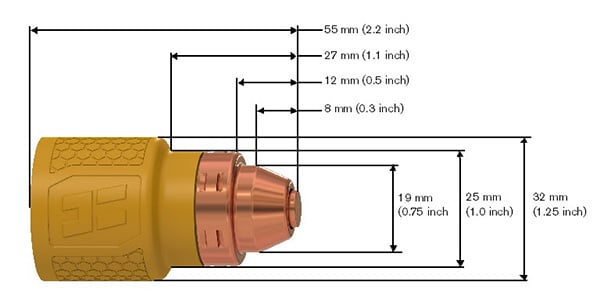

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Hypertherm cartridges for Powermax systems are manufactured to uphold our high standards for quality and reliability. As part of the manufacturing process, we test-fire each cartridge to ensure proper assembly and function. As a result, there may be burn marks on the tip of the cartridge. This is normal and not a sign of damage.